THINGS YOU NEED TO KNOW ABOUT TRANSMISSION OIL

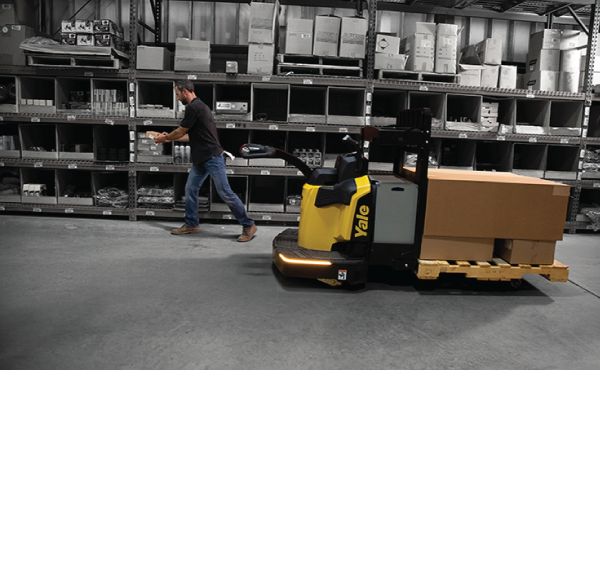

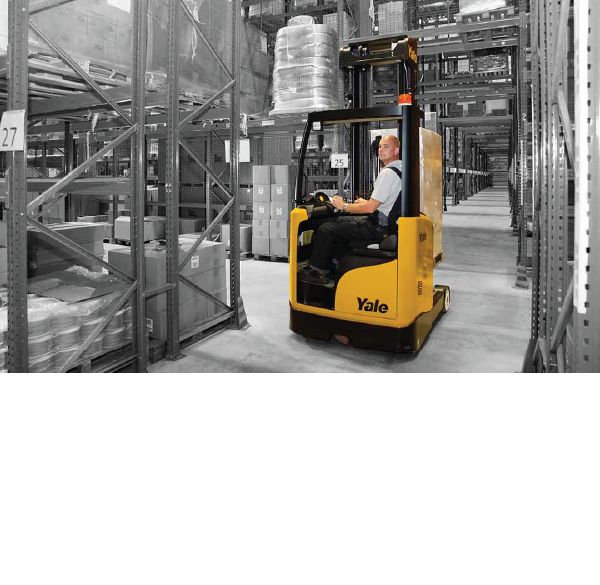

Forklift transmission is one of the important parts which helps to adjust the movement of the forklift. Based on the forklift transmission, we can partly judge the quality of a forklift.

In order for the forklift transmission to operate smoothly and efficiently, the role of forklift transmission oil is very important. Let’s find out what you need to know about forklift transmission oils with Yale Forklifts Vietnam through the below article:

Table of contents:

1. What is transmission oil? Is transmission oil important?

2. The common type of transmission oil

3. When do we need to change the transmission oil?

S4. imple guide to change forklift transmission oil

1. What is transmission oil? Is transmission oil important?

Forklift transmission oil is a type of lubricant that is used to lubricate the transmission system. The requirements for the lubrication and anti-wear ability of the forklift transmission oil are very high so it can help the forklift operate smoothly, achieve stable performance and limit damage to the gearbox which has a complex structure and is difficult to repair.

The forklift transmission oil is very important because of the below effections:

- Lubricate

- Cooling

- Limited the abrasion

- Noise reduction

- Oxidation restriction

Forklift transmission oil plays an important role

2. The common type of transmission oil

Manufacturers usually use indexes to classify forklift transmission oil. The common indexes are API, SAE, VI, etc… In addition, the additives which are added in the transmission oil are also important because it affects the quality of the oil.

2.1. Forklift transmission oil’s API index

API is an acronym for American Petroleum Institute which is used to reflect the quality of the transmission oil.

API quality level is classified into SA, SB, SC… (lowest is SA). Currently, the highest transmission oil quality based on API index is SM.

API index reflects the quality of the transmission oil

Science and technology develop faster and faster. Forklift engines are also improved to work in harsh environments (in terms of temperature, pressure, etc.)

Oils with low API index cannot meet the requirements of engine operation so manufacturers have added additives to transmission oils to improve quality.

Additives that are usually added in the transmission oil: antioxidants, anti-emulsifiers, foaming agents, improving resistance to temperature, pressure, water separation, anti-cracking of oil, etc… Therefore, the common API index of transmission oil is usually from SG grade or higher.

2.2. Forklift transmission oil's SAE index

SAE stands for Society of Automotive Engineers - Society of Automation Engineers. For users, the SAE index is a symbolic index for the viscosity of the transmission oil.

According to the SAE index, we have 2 types of viscosity which are single-grade and multi-grade.

Single-grade transmission oils will typically have SAE indexes as 40 and 50 which typically decrease viscosity rapidly when the temperature increases.

Multi-grade transmission oils (SAE 10W-40, SAE 15W-40) offer more stable viscosity at higher temperatures than single-grade oils and oil dilution will remain the same as temperatures drop.

Therefore, single-grade oils are rarely used in the cold season while multi-grade oils can be used all year round.

2.3. VI index of forklift transmission oil

Another index showing the viscosity of a transmission oil is VI - short for Viscosity Index. This index represents the change in oil viscosity when the temperature changes. The higher this number, the more stable (or less variable) the transmission oil is with temperature.

On the market today, most transmission oils have a VI index of 90-110, some of the oil types also can have this index up to 180.

The quality requirements of forklift transmission oil are getting higher and higher

2.4. Forklift transmission oil’s additives

Manufacturers always add additives to enhance the properties and roles of the oil, such as:

- Cleaning additive: preventing the formation of dirt, soot, etc

- Anti-corrosion additive: create a film that covers metal parts, reducing friction and limiting oxidation.

- Additives to improve viscosity: help stabilize the oil's viscosity, ensure the lubricating ability of the oil and limit the influence of temperature on the viscosity.

- …

3. When do we need to replace forklift transmission oil?

During operation, the oil will accumulate sediments or metal chips due to the friction process…. In addition, forklift transmission oil does not evaporate and contains a lot of important additives, even if the forklift is not in operation, these additives will gradually lose their effectiveness over time.

Therefore, replacing the forklift transmission oil periodically will help the forklift operate more stably, more efficiently with a longer life.

The transmission bridge compartment and the forklift's transmission compartment are different from other vehicles, there is no separate separation.. Therefore, the transmission oil change and the bridge oil change must be done at the same time.

Forklift transmission oil needs to be changed periodically

Each manufacturer will have different recommendations for replacing transmission oil, but in general, it should be replaced periodically after about 1 year or 2000 hours of operation.

4. Simple guide to change forklift transmission oil

The forklift transmission oil replacement procedures are quite simple, customers can completely check and replace it according to the following suggested steps:

Step 1: Raise the front wheels and undercarriage high to create space so that you can work easily.

Step 2: Drain the used oil out of the tank. Customers can open the screws on 4 sides to check the new oil level.

Step 3: Add new oil until the oil flows out at the hole across the transmission bridge, then it is considered to have poured the necessary amount of oil.

Step 4: Tighten the screws on 4 sides and close the oil filler cap. Then lower the forklift.

Step 5: Let the car start the engine for 5-10 minutes so that the oil can fully reach the transmission.

The above article is the basic information and need to know about forklift transmission oil. Please contact Hotline: 0896.461.728 so that Yale Forklifts Vietnam has the opportunity to consult Customers who need more information or support about forklifts and forklift spare parts.

_20230206052219.jpg)

-(2)_20230220041419.jpg)

-(1)_20230224113508.jpg)

-low_res-scale-2_00x_20230704111442.jpg)

-v4_20230706104404.jpg)

_20230712035828.jpg)