5 Tips for a Longer Lifespan of Forklift Battery

Any forklifts need to be operated and maintained properly for a longer lifespan. Especially with electric forklifts, the battery is the "soul" of the truck, and must be well-maintenance to bring the highest performance. In today's article Yale Forklifts Vietnam will share 5 tips that any business should know to increase the lifetime of electric forklifts.

Table of content

1. Maintenance Goals

2. Tips for Batteries to Decrease Damages

3. Preparation for Downtime Period

4. Invest in Maintainance Training of Staff

5. Use maintenance and repair services of a replicable company

1.Maintenance Goals

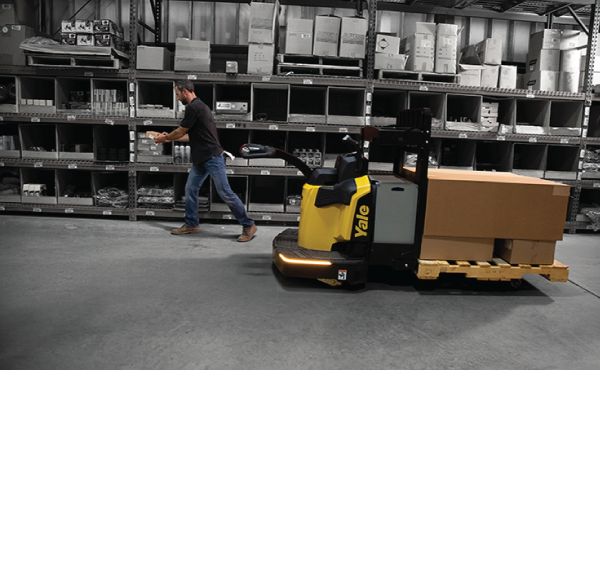

Yale electric forklifts or other electric forklift brands now have an advanced battery design that requires little maintenance. However, as recommended, the end-user should have a routine maintenance schedule every 6 months for electric forklifts.

_20220803104400.jpg)

The end-user should have a routine maintenance schedule

In addition, a daily checklist after every shift is also necessary. A clear schedule and plan prove helpful to track upkeep

2. Tips for Batteries to Decrease Damages

Always periodically inspect electric forklift parts, especially the battery

Forklift operators must know routine checks to ensure safety. It is essential to charge, clean, and check batteries regularly along with electrolytes.

Regular cleaning is necessary for batteries. In this way, you can decrease the build-up of dirt and dust. Remember, dirt and dust can damage your batteries and reduce their lifespan.

3. Preparation for Downtime Period

For a closure period, you have to take essential measures to protect your electric forklift.

If you are preparing for downtime, then make sure to disconnect or switch off batteries from the main supply. In this way, you can avoid battery discharging.

You can increase the danger of irreparable damage by allowing discharging batteries to almost 20%. Remember, you should not leave forklifts inactive for a longer duration.

Try to refresh-charge your batteries frequently. With periodic maintenance, it is also possible to keep your batteries in the best condition.

4. Invest in Maintainance Training of Staff

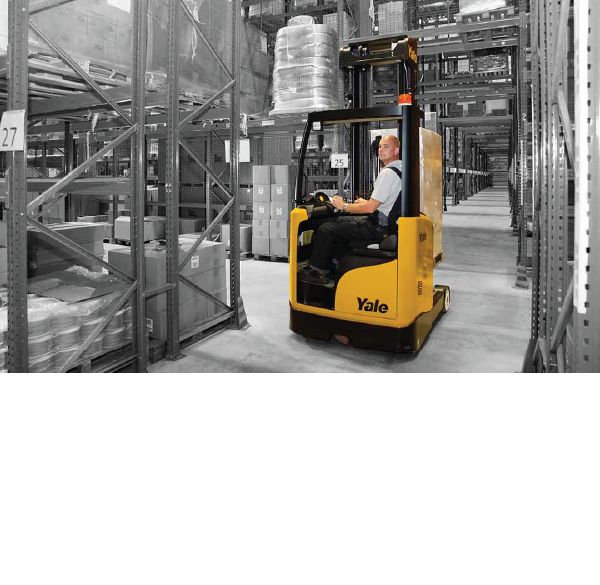

Today's Yale forklifts have been engineered to optimize performance, reduce engine wear, and be much more efficient than before. However, to protect your investment, ensure training of your staff. Indeed, training is necessary for the safety of your workforce.

After education and training, the operator will feel responsible and confident. Moreover, it will become an excellent motivator.

Yale Forklifts Vietnam's experienced technical team.

In the rental and sales business, Yale Forklifts Vietnam also supports training the team on how to operate forklifts properly, efficiently and professionally. In case you need this service, please leave your information below to receive advice from us.

5. Use maintenance and repair services of a replicable company

Covering the issues mentioned above, it can be seen that in order for an electric forklift to maintain its life, businesses need to know how to properly maintain the truck and have a good team to do this job. Not all businesses have the resources and expertise to maintain the "performance" of the truck. Therefore, using maintenance services from a reputable company is a necessary choice.

Yale Forklifts Vietnam, with nearly 20 years of operation in the material handling equipment industry, deeply understands the need to ensure stable and efficient operation of forklifts that play a very important role in the operation of the businesses. Therefore, the maintenance service of electric forklifts of Yale Forklifts Vietnam is prioritized to be performed professionally, thoroughly and efficiently.

In addition to providing performance maintenance services for the forklift trucks of the Yale Forklifts brand, the engineers of Yale Forklifts Vietnam are also very knowledgeable and confident in performing services for other forklift brands on the market such as: Komatsu, Linde, Jungheinrich, Mitsubishi, Nissan, TCM, Hyster, Toyota...

Customers who want to ensure their forklifts always operate stably and efficiently, please contact Yale Forklifts Vietnam via Hotline: 0896.461.728 for advice on specialized forklift maintenance and repair services by a professional and dedicated staff .

Here are 5 tips to help businesses maintain and increase the life of electric forklifts. The maintenance should be performed periodically which not only affects the quality of the truck, but also directly affects the safety of the goods lifting process of the businesses.

To know what scope of work that the operator needs to check each day, please leave your information to receive a checklist built by a team of experts at Yale Forklifts Vietnam. Please contact the hotline 0896.461.728 to receive advice on services of purchasing new forklift - purchasing used forklift - electric forklift rental - electric forklift maintenance.

_20230206052219.jpg)

-(2)_20230220041419.jpg)

-(1)_20230224113508.jpg)

-low_res-scale-2_00x_20230704111442.jpg)

-v4_20230706104404.jpg)

_20230712035828.jpg)